Against the backdrop of a highly disruptive and volatile market environment, supply chain risk management has risen to the top echelons ofboardroom agendas. Vivianne Courte-Rathwell, a Consultant at Sourcing Champions, explains why the concept is gaining importance – and outlines some of its main benefits.

A review of the historic supply chain disruptions of the past few years would hardly be news to anyone. In an unprecedented ‘risky’ period, with a pandemic, climate change, a Russia-Ukraine war, geopolitical pressures, and much more, it is no surprise that global supply chains have recently been dealing with heightened risks.

However, it is key to keep in mind that such disruptions do not only occur in unfortunate periods of history. Risks are by nature ubiquitous and unpredictable, and that means that leaders need to embrace an approach that helps them mitigate, adapt and learn.

In 2012, there was a disastrous tsunami in Japan which impacted the automotive industry worldwide. In 2015, an immense explosion at one of the largest ports in the world, the Port of Tianjin, caused significant costs and losses. In 2018 the US – China trade war negatively impacted profit margins and created tense times of uncertainty.

It is impossible to conceive to avoid all risks. Instead, the key is to mitigate significant damages through foresight in strategic management.

After the tsunami of 2012, automotive organizations had nowhere to turn as many realized that their single source of materials was Japan. Even OEMs with a multi-sourcing strategy encountered issues because many tier-1 suppliers procured materials from the same tier-2 supplier. As a result, the challenges of tier-2 suppliers became a direct concern as well.

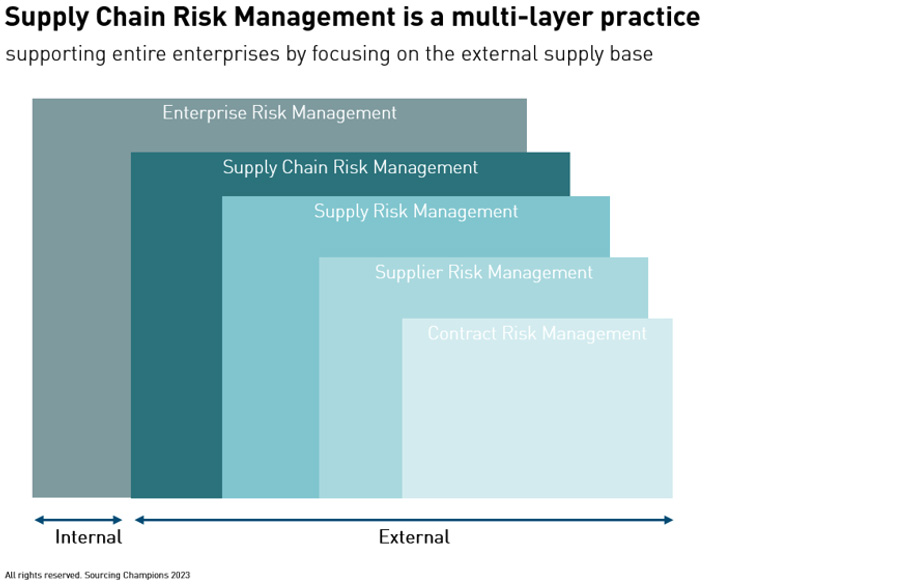

Had there at the time been a multi-layer supply chain risk management (SCRM) program in place, these issues could have been (easily?) avoided and impact to the business would have been minimized. SCRM tools and processes act as guardrails and shields protecting the business from potential perils, hence providing a competitive advantage.

Read more at The growing importance of supply chain risk management

Leave your comments below or write to us if you have any questions.