In 2023, retailers will be able to leverage next-generation business intelligence and augmented analytics in a number of ways to improve their operations and drive growth. The current generation of BI tools and platforms has already had a major impact on the way businesses operate. However, the next generation of BI is expected to be even more powerful and transformative.

Here are eight key areas where retailers should consider deploying next-generation BI to drive major business impact and further insulate in times of uncertainty:

1. PERSONALIZED MARKETING AND CUSTOMER EXPERIENCE

Augmented analytics can help retailers analyze customer data and create personalized marketing campaigns and shopping experiences. For example, a retailer could use augmented analytics to identify customers who are likely to respond to a particular type of promotion, and then target those customers with personalized marketing messages.

2. INVENTORY MANAGEMENT AND SUPPLY CHAIN OPTIMIZATION

Next-generation business intelligence can help retailers optimize their inventory management and supply chain operations. For example, a retailer could use BI to analyze sales data and forecast demand for particular products, helping them avoid overstocking or running out of popular items.

3. FRAUD DETECTION AND PREVENTION

BI and augmented analytics can also be used to identify and prevent fraudulent activity. For example, a retailer could use these technologies to analyze customer behavior and identify patterns that may indicate fraudulent activity, such as unusually large purchases or suspicious payment methods.

4. PRICE OPTIMIZATION

BI and augmented analytics can also help retailers optimize their pricing strategies. For example, a retailer could use these technologies to analyze sales data and identify the optimal price for a particular product, taking into account factors such as competition, demand, and margin.

5. INTEGRATION WITH OTHER TECHNOLOGIES

Next-generation BI is also expected to be more closely integrated with other technologies, such as the Internet of Things and blockchain. This will allow retailers to take a more holistic approach to data analysis, gaining insights from a wide range of sources.

6. REAL-TIME ANALYSIS

Another key trend in next-generation BI is the ability to analyze data in real time. This will allow organizations to make timely, informed decisions based on the most up-to-date information available.

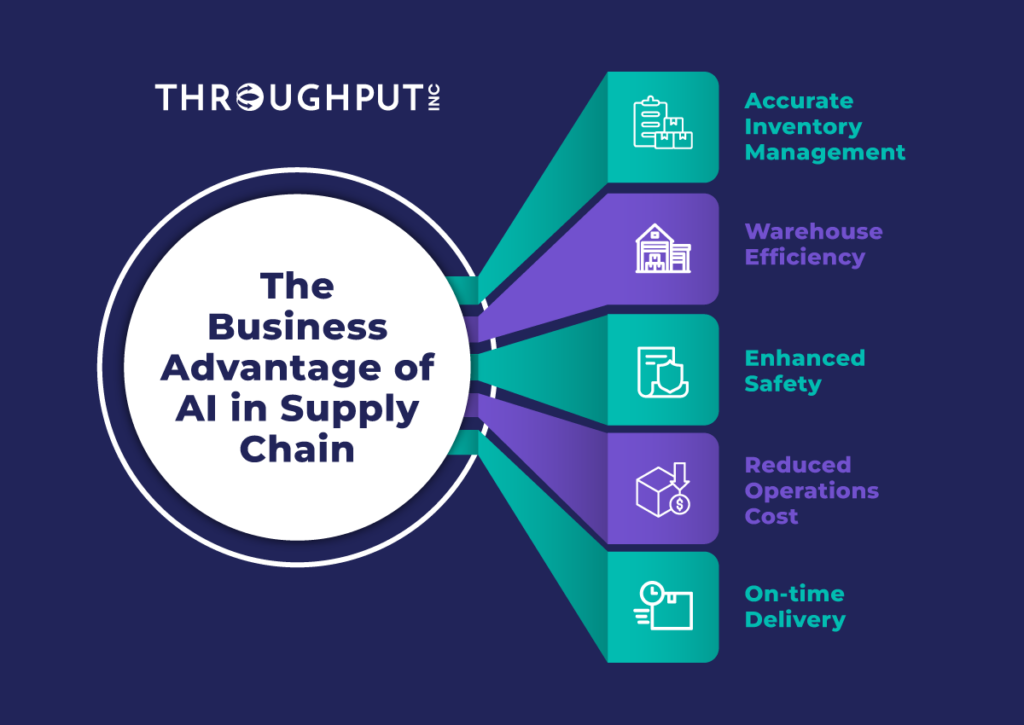

7. ARTIFICIAL INTELLIGENCE AND MACHINE LEARNING

One of the major trends in next-generation BI is the use of artificial intelligence and machine learning to analyze and interpret data. With these technologies, BI systems will be able to automatically detect patterns and trends in large datasets, providing insights that would be impossible for humans to uncover on their own.

8. ENHANCED COLLABORATION AND ACCESSIBILITY

Finally, next-generation BI is expected to be more collaborative and accessible than ever before. With advanced visualization and collaboration tools, teams will be able to work together more seamlessly, sharing insights and making decisions in real time.

Read more at How retailers can leverage next-generation business intelligence and augmented analytics in 2023

Please subscribe to us for updates and send us a message for a discussion. You also can leave your comments below.