Performance management has room to improve. According to Gartner research, 52% of chief human resource officers (CHROs) believe they are not rewarding the right behavior in employees, and only 32% of HR business partners believe performance management delivers what employees need to perform.

Because of this, in the last five years, 74% of organizations have significantly changed their performance management processes. “Companies are implementing a variety of new practices, from linking pay to project performance to eliminating performance reviews entirely,” says Benjamin Loring, Research Director at Gartner. “The real unlock, however, is making performance management useful to both managers and employees with this six-part roadmap.”

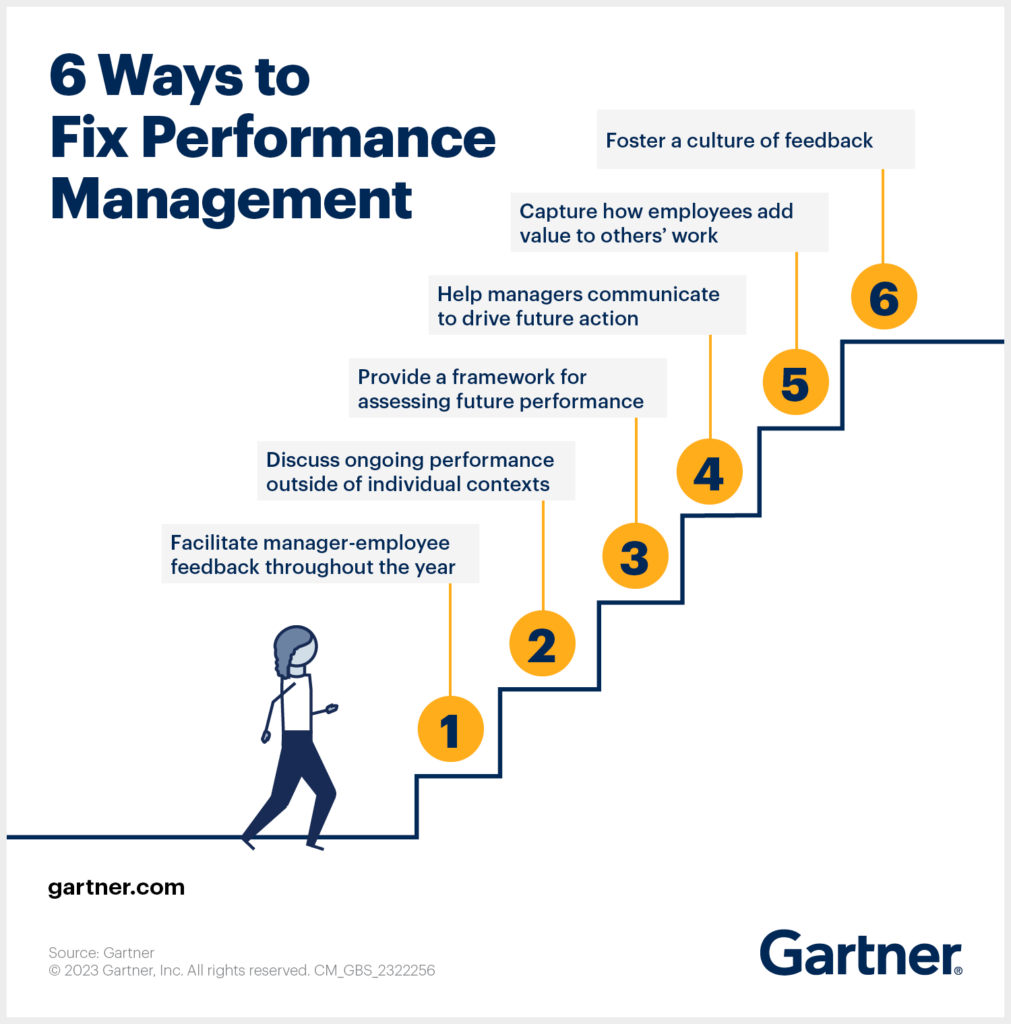

Six ways to fix performance management

Improve performance management by considering the amount of conversations you have, the lens through which you look at performance, and the style of feedback you provide.

Ongoing conversations

No. 1: Encourage ongoing manager-employee feedback throughout the year

Create a mutual understanding of what type of feedback employees need to be successful and enable them to own and schedule feedback conversations by educating them on the types and frequency of dialogue that can occur.

No. 2: Promote discussions beyond individual contexts

To enact this, promote team goal-setting. Encourage team members to reflect and develop their individual goals for teams to review for alignment, impact, relevance and overlap. Similarly, create a space for employees to provide feedback to managers to reinforce employee agency and power in feedback conversations.

Forward-looking reviews

No. 3: Develop a framework for assessing future performance

Assess employees’ development readiness — their capacity, ability and willingness to take on professional development at a given point in time — not just performance, and align coaching conversations, and support to their true needs. This may require evolving how you evaluate growth and reframing the value of the process, while also navigating ambiguous situations and meeting organizational needs.

No. 4: Encourage managers to communicate actions needed for future success

Help managers provide feedback on what skills their employees need for the future, in addition to reflecting on their past accomplishments. Increasing transparency of skills across a team encourages cohesiveness, coaching and on-the-job development.

Peer feedback

No. 5: Gather feedback from co-workers on how employees help fellow team members

A huge part of performance management is feedback from colleagues. Guide managers on how to identify sources of feedback based on who has knowledge of an employee’s work, rather than limiting feedback to the employee’s formal relationships. Peer assessments are a good way to hold employees accountable for demonstrating critical behaviors and get a more comprehensive understanding of their contributions. Just be sure to develop evaluation guidelines that focus on outcomes.

No. 6: Foster an environment of feedback

Encourage employees to recognize their peers’ contributions to create comfort and confidence regarding feedback exchanges. Create a simple approach to seeking and requesting feedback and frequent prompts to focus managers on recognizing and reinforcing good behaviors throughout the year.

Read more at 6 Ways To Transform Performance Management To Deliver What Employees Actually Need

Leave your comments below and contact us for discussions